Long Willow Flute—Safeguarding an Embodied Practice

Background

The traditional long willow flute is made in the springtime. A trained practitioner can make a flute in some fifteen minutes. They are not very complicated to make as long as one knows exactly how to do it. To make a willow flute the practitioner just needs a sharp knife and fresh willow (Salix caprea) harvested at the right time of the year. The time frame for making them is only one month each year, in spring. As summer and fall moves on, the willow will get dry, and it will not be possible to even play the flute anymore. As is the case with intangible cultural heritage in general, the long willow flute, therefore, must be recreated again and again and passed from generation to generation in order to survive. Making these flutes used to be common knowledge in several places in Norway, but today there are not many practitioners left. The flutes are used for playing traditional folk tunes.

Watch a video on our Youtube-channel. Silje Hegg from Rauland playing the long willow flute.

The long willow flute is the long type, forty to eighty centimeters and gives many tones, at best sixteen different tones. Melodies can thus be played on this type of flute, which distinguishes it from the simpler pipe or flute that has only one note.

“Seljefløyten” (The Willow Flute) 1889. Christian Skredsvig (1854-1924) Oil on canvas. Photo: The National Museum. Wikimedia Commons: PD.

Objectives

In the Mountains

Our willow flute project took place in the mountain area in Norway, in Rauland at the end of May 2016, and it was a collaboration among the organization Norwegian Crafts Institute and two local NGOs Raulandsakademiet and Rauland Husflidslag. The aim/objective of the project was to make a long willow flute in the tradition of a local community member, Tarjei Bakken, who had passed on the tradition to Jon Bojer Godal. There are several things in life that can be communicated through books and videos, but according to our experience, the best way for passing on crafts is through a practical approach. To pass on crafts, it is a bearing principle for Norwegian Crafts institute that we needed to organize through practice, in situ.

There is a Chinese saying that if you want to understand something, you have to chew it in your mouth (Cohen et al, 2011, p.465)

How it was done

Projects at Norwegian Crafts Institute- passing on the craft

Each year the Norwegian Crafts Institute carries out about thirty on-going projects relating to several trades with a special emphasis on living knowledge that is in danger of disappearing. The most important aspect of these projects is the provision of knowledge to professionals though interactions with a bearer of a tradition. In this way knowledge is passed on to a new generation of craftsmen.

The most important person in these projects is always the bearer of the tradition. The bearer is the one with the living knowledge, which is the object for safeguarding. It’s the bearer’s knowledge we are aiming for. In this case the bearer was Jon Bojer Godal, who is a well-known communicator of action-borne knowledge, a term I will explain in the next paragraph. Jon Bojer Godal is 84 years old, and therefore, it is particularly important to make sure that his knowledge is passed on to the next generation.

I was not aware that Jon could make these types of flutes, so in this case it was a member of the local community in Rauland, Ann Mari Jore, who knew about this hidden treasure, and took the initiative. She made a phone call to the institute and asked if we could organize a project. She explained that there were several members of the local community who were eager to learn how to make this kind of flute. Including herself there were five local practitioners that were all teachers working in elementary schools and in junior high schools. We figured out that in this way we could pass this on to a new generation, in the community. It is especially interesting that most of the professionals in the project live and work in the flute’s geographical area of tradition, around and in Rauland, where the bearer grew up and learned this tradition. For the institute it was important that members of the community were taking the initiative and invited us to assist. We believe that the importance of community involvement should never be underestimated. This is also underlined by UNESCOs approach to the 2003 Convention and can be exemplified by the ICH-2 form (For the Representative List) where the term community is repeated twenty-five times in the application form.

Action-borne Knowledge

The institute uses the term action-born knowledge to describe the fact that knowledge of a craft has its basis in both practice and action. The term is used to describe the approach to the method for passing on traditional crafts. Atle Ove Martinussen describes action-borne knowledge as “the sum of experience and skills that have been passed on from one generation to another in a knowledgeable fellowship of action and culture”. (Weihe et al, 2009., p.124)

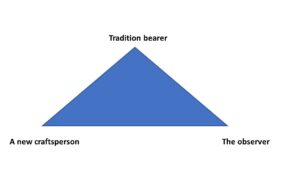

The model can be described as a triangle model consisting of three relations: the senior master, often called the tradition bearer, a new craftsperson, and lastly, the observer:

The Bearers of the Tradition

We understand the bearer as a person carrying the knowledge and skills of several generations within him- or herself and he or she is a part of a living tradition. The knowledge of the bearer is regarded as something important that needs to be safeguarded. The tradition bearer is in most cases recognized by the community of his or her trade in the fellowship of craftspeople.

The New Craftsperson

The new craftsperson is the one who is willing to learn. Often this person is quite skilled, and therefore, capable of receiving knowledge handed over from the bearer. The relation between the bearer and the new craftsperson is important, and often the projects are organized on the initiative of either the bearer or the new craftsperson.

The Observer

The observer’s task is to observe, document, and record with video and/or photo in addition to taking notes of what is going on between the tradition bearer and the new craftsperson. The observer’s role is to be a fly on the wall and should not disturb the transmission process. Nevertheless, the observer should know the craft and the technique to know what to emphasize in the documentation. Therefore, we often use the new craftsperson to do the documentation.

Too Many Participants?

Nevertheless, we had our doubts in this case if the project would be fruitful. In the projects the Norwegian Crafts Institute have run, our experience is that the traditional, and preferable way to learn crafts is one on one, from the master to the apprentice, as it has been successfully done for thousands of years all around the world.

The apprentice model is maybe the most ancient of all educational models. We know it from parenting where the child imitates the adult from the earliest stages. The traditional apprenticeship is are essentially based on the same principle of imitation and has been applied over centuries, particularly in the crafts and vocational fields (Ruskin Mill, 2013-14, p.28).

The institute has experienced previous projects that failed because there were too many people involved. Some years ago, we ran a project with one master and two younger blacksmiths. The old bearer quickly identified the most skilled one and started to concentrate on him while the other blacksmith was left alone without any attention from the bearer. The bearer had chosen the blacksmith that was most capable of receiving and focused on him. On the other hand, we once worked with a wooden ski maker and two younger learners, and they both learned in a nice way, and they are both still practicing traditional ski making today. So, one might fail with more than one learner, but it might also work. Because of our previous experience we discussed this challenge up front, and that it was important for us that the main person in the project, the bearer Jon Bojer Godal, accept and was comfortable with the framework, and that he could work with five practitioners at the same time. As the bearer had long experience as a teacher, we felt this could work.

Hunting for Suitable Wood

We decided to start our project on a spot between the woods and a river, where the willows were wet and fresh. In the nature. Identifying the proper willow is and crucial for succeeding. The ability to interact with and understand nature is also underlined by the philosopher Sennet who emphasize how crafts brings us closer to what he describes as the natural world. Sennet claims that sustainable means to be closer to nature:

Sustainable suggests living more at one with nature, as Martin Heidegger imagined in his old days establishing an equilibrium between ourselves and the resources of the world (Sennet, 2008 p.12-13).

The good spot for suitable willow was identified by the bearer in front. He suggested that the willow should be “suitably thick” and long enough. 3/4 to 7/8 inches is good, he said. The length should be about two feet, sixty to eighty centimeters. It is important to harvest the willow for this purpose in the spring when it is possible to remove the bark easily. According to the bearer “the best harvest time for willow is when the bird cherry is in bloom”. The workpiece should have the least possible irregularities, so that it is easy to loosen the bark without it cracking. Once a good item has been found, it is cut to a suitable length.

Looking for proper willow together with the bearer, Jon Bojer Godal.

This is another principle that we believe is important. When organizing a project, it should, if possible, take place on the bearer’s geographical home ground. This is where they feel confident and are familiar with the surroundings. In this case, we were at the place in which the bearer grew up. As identifying the willow suitable for making a flute was crucial for the project, this was undoubtedly of importance in this case. In general, it is not wise to move the bearer out of their environment to teach. It might work in academia, but rarely for the lumber jack, or in our case, the willow flute maker

I will not dwell at the technical details of the flute making, but rather introduce another perspective. As the bearer went along showing us how to make the flute, he also unveiled several rules and sayings that were crucial for the making. I will give two examples:

When making the smaller flutes, or pipes, we always use a magic rhyme while we are knocking on the bark with the handle of the knife. I have always used these rhymes when teaching how to make the smaller flutes. In Norway there are more than 800 magic rhymes registered for loosening the bark. In this case, and for the long willow flute, the bearer was crystal clear that no magic rhymes should be recited or knocked on the bark, as this will weaken the strength of the bark. This was very important. He used another method. The bearer described removing the bark as the most difficult part of the job. He said:

One should feel that it releases and does not twist more than just suitable. It is, so to speak, a meditative exercise that requires inward concentration. Distraction must not be. We should feel in the hands and we feel best when the eyes are half open and the mouth half open. We direct the concentration to the left-hand which twists.

The bearer explains how to measure the flute by using the body:

Alen suggests forearm. Danish-Norwegian alen (24 inches = 62.8 cm) is the forearm measured from the elbow and to the tip of the middle finger (= 18 inches) + a fist (= 6 inches). A good length of flute material is one alen + fist grip, which will be about 75 cm, but we often have to accept something shorter.

Later he explains:

…Then take a grip with one hand around the log and with the other around the shredded bark and gently twist the bark loose. To continue down until the bark is loosened all the way down to the last three finger widths of the thick end.

Using the body when measuring is common among craftspeople. Not just for flute makers, but also for boatbuilders and other traditional trades. I remember I was once in India, invited by the NGO Banglatanak.com and we were watching woodworkers carving mermaids for sale. In front of them they had a tree, and when they needed a piece of wood, they walked over to the tree and cut of a piece. They took the piece of wood, sat down and carved a new mermaid. In the room it was a pile of mermaids, and they were all the exact same size. How was that possible? There were no measure sticks around. After a while I understood what happened: They used their body. And just as Jon Godal used his forearm for measuring the length of the flute, the woodworkers in West Bengal did the same when measuring their mermaids.

The ethnologist, architect and the historian might have a lot of knowledge about crafts while the craftsperson’s knowledge is embodied knowledge. (Falk, 2008, p.11).

Demonstrating a proper flute

Did it Work?

Four years has passed since the project, and to identify the outputs, we asked the practitioners if they had made any long willow flutes after the project. And if so, if they had passed the knowledge on to a new generation. It would also be interesting for us to know if the participants had used the documentation material as a support in their work and found it useful.

There were five practitioners in the project, all a part of the local community, and in a position to maintain and pass on the knowledge to a new generation. In addition to the five local practitioners, I was there. I was mainly an observer, responsible for the documentation. Nevertheless, I was also participating as a woodworker myself.

Of the five local practitioners, four have not made any flutes after the project. Of these four, one did try once but failed.

Luckily the last one of the five, teacher and practitioner Dag Larsen, has continued the practice, making long willow flutes every year after the project. He has also passed the knowledge about making willow flutes to a new generation, to the schoolchildren in the school where he works, and as he points out “to some friends and people drifting by along the road.” Dag Larsen further claims that he never used the documentation, because “he had the knowledge in his hands.” Larsen’s comment is questioning the necessity of written documentation material, and it is therefore an interesting comment to the triangle model above. It underlines the point that the most important part of the project is the transmission between the bearer and the new craftsperson.

Some of the finished flutes

In my case, I have made several flutes each year to stay in shape and keep the element alive. I also made a willow flute directly on national radio, where the professional flutist played my flute afterword’s, broadcasted to all of Norway. In 2019, I wrote a chapter about this tradition published in my book Den store spikkeboka (2019)

Even if the documentation of the project resulted in an extremely detailed description containing pictures and illustrations on how to make them, nobody I have talked to afterword’s has managed to make a flute without learning directly from a person. This shows how important it is that the newly acquired skill must be actively kept alive by the learner through practical work/further practice. And I know they have tried. I can, therefore, conclude that the detailed documentation we made has until this day turned out to be useless for others than myself when it comes to really make a willow flute. However, it may be useful to create interest and understanding about the willow flute tradition, and for future flute makers.

Crafts can be simple, but also difficult, as the devil is always in the smallest details, and the best way to learn crafts is, as pointed out earlier, in practice, in situ. In this case from somebody that knows how to make a willow flute teaching someone how to make one. Making a long willow flute is just one of several projects that the Norwegian Crafts Institute carries out every year. In general, and according to more than thirty years of experience in the field, we find it fruitful to follow these five principles when safeguarding traditional crafts:

- Passing on the knowledge one on one (master-apprentice model) is the preferable way

- The transmission / learning should preferably take place in the tradition bearers’ environment, in situ

- The program should be carried out in cooperation with the community

- The transmission should take place through a practical approach

- Documentation can easily be overrated. The most important happens between the bearer and the learner

I hear and forget. I see and remember. I do and understand.

Xunzi (ca. 310 – 235 BC ) Confucian philosopher